Tube Cleaning Equipment

Why Choose Us?

Variety of Products

We can design, customize and manufacture high-pressure cleaners, industrial cleaning machines, sewer drain cleaning machines, high-pressure pumps, pressure test pumps, automatic cleaning systems, etc. for customers. We can also provide a variety of related accessories.

Wide Range Of Applications

Our cleaning machines can be used in industrial and commercial cleaning applications. They can meet various needs such as commercial surface dirt cleaning, industrial pipe/pipe/tank cleaning, hull rust removal and painting, sewer drain cleaning, pipe/valve pressure testing, concrete surface roughening, concrete cutting, etc.

Advanced Production Equipment

Our factory is equipped with many advanced production equipment such as lathes, grinders, plate rolling machines, punching machines, and electric welding machines. We also conduct strict quality testing on our products to ensure they meet customer requirements.

Professional Service

We have a professional team to provide professional introduction and product recommendations. After the machine is manufactured, we will provide pictures and test videos for confirmation. In addition, we have a professional technical team to provide technical support to customers, and customers can enjoy our one-year warranty service.

What is Tube Cleaning Equipment?

Tube cleaning equipment is a device responsible for cleaning the inner walls of various pipelines, eliminating the impact of various dirt caused by long-term use on the pipeline's transportation efficiency, and extending the service life of the pipeline. Tube cleaning equipment can select an appropriate pressure level based on the composition of the scale and cleaning requirements. It will not cause physical damage and can keep the surface of the reactor smooth, making it difficult for scale to adhere to the reactor.

Industrial Hydro Water Jet Blasting Machine

Introducing our powerful 22000psi water jet cleaning system, designed to tackle the toughest cleaning challenges with unmatched precision and efficiency. With its incredible pressure, this system delivers a high-velocity water jet that effortlessly removes stubborn dirt, grime, coatings, and deposits from surfaces, leaving them immaculately clean.

Industrial Hydro Water Jet Cleaner Machine

Whether it's industrial equipment, pipelines, tanks, or challenging environments, our 22000psi water jet cleaning system ensures optimal cleaning results, saving you time and effort while maintaining the highest standards of cleanliness and performance.

Industrial High Pressure Water Jet Cleaner Machine

Introducing our powerful 22000psi water jet cleaning system, designed to tackle the toughest cleaning challenges with unmatched precision and efficiency. With its incredible pressure, this system delivers a high-velocity water jet that effortlessly removes stubborn dirt, grime, coatings, and deposits from surfaces, leaving them immaculately clean.

Industrial High Pressure Water Jet Cleaning Machine

Introducing our powerful 22000psi water jet cleaning system, designed to tackle the toughest cleaning challenges with unmatched precision and efficiency. With its incredible pressure, this system delivers a high-velocity water jet that effortlessly removes stubborn dirt, grime, coatings, and deposits from surfaces, leaving them immaculately clean.

Industrial Hydro Blasting Equipment

Whether it's industrial equipment, pipelines, tanks, or challenging environments, our 22000psi water jet cleaning system ensures optimal cleaning results, saving you time and effort while maintaining the highest standards of cleanliness and performance.

Industrial Hydro Blasting Machine

With its incredible pressure, this system delivers a high-velocity water jet that effortlessly removes stubborn dirt, grime, coatings, and deposits from surfaces, leaving them immaculately clean. Whether it's industrial equipment, pipelines, tanks, or challenging environments, our 22000psi water jet cleaning system ensures optimal cleaning results, saving you time and effort while maintaining the highest standards of cleanliness and performance.

Explosion Proof Hydro Balster Equipment

Designed to efficiently remove stubborn deposits, blockages, and contaminants, it is highly effective in cleaning industrial pipelines, tanks, heat exchangers, and surfaces. Equipped with cutting-edge pump technology and specialized nozzles, this equipment generates a focused and forceful water jet that penetrates deep into the target area, providing thorough and efficient cleaning results.

Petrochemical Cleaning Hydro Balster Equipment

1200bar high pressure hydro jetting equipment, a state-of-the-art solution for tackling the toughest industrial cleaning challenges. With its impressive pressure rating of 1200 bar/18000psi, this equipment offers exceptional power and precision for various hydro jetting applications.

Explosion Proof Petrochemical Cleaning Hydro Balster Equipment

1200bar high pressure hydro jetting equipment, a state-of-the-art solution for tackling the toughest industrial cleaning challenges. With its impressive pressure rating of 1200 bar/18000psi, this equipment offers exceptional power and precision for various hydro jetting applications.

Advantages of Tube Cleaning Equipment

Reducing the overall cost

By shifting the focus to the introduction of a tube cleaning equipment, people will be definitely able to carry out things very easily and further, there will be no scope for any kind of loss of efficiency at any step. All of these options will be definitely helpful in supporting the overall production capacity and the best part is that the cost related to the cleaning interactions will be the bare minimum in the whole process. Basically, people will be able to minimise the overall cost and ultimately everybody will be able to enjoy the positive impact of the basic cleaning and operating procedures without any problem.

Minimising the downtime of the operations

Formulating the best possible type of cleaning schedule in terms of using the tube cleaning equipment is also considered to be a good idea so that chances of downtime will be the bare minimum. All of these options will be definitely helpful in making sure that unpleasant and environmental best issues will be eliminated and further everything will be translated into significant savings of time as well as money.

Regular cleaning will be promoted

Using the option of a tube cleaning equipment is definitely considered to be a very good idea so that everybody will be able to promote the element of regular cleaning very successfully and further every cycle of cleaning will be significantly improved. All of these options will be definitely helpful in making sure that everything will be streamlined very successfully and people will be able to enjoy a retention rate of approximately a hundred per cent without any problem.

Extending the life of the equipment

Whenever organisations will be depending on the right kind of tube cleaning equipment suppliers then definitely there will be no scope for any kind of problem and the overall life of the equipment will be significantly improved. All of these options will be definitely helpful in improving the premature equipment system without any kind of doubt and the heat transfer efficiency will be sorted out very successfully. All of these options will be helpful in making sure that there will be no scope for any kind of problem in the overall capacity level.

People can easily save on chemicals and manual cleaning

Using the option of a tube cleaning equipment is definitely considered to be a very good idea so that this charge of cleaning chemicals will be eliminated in the whole process and ultimately there will be no scope of any kind of effort on the basis of manual cleaning. Basically, people will be able to enjoy a significant factor of support without any kind of doubt and the overall electric energy consumption will be significantly reduced.

Types of Tube Cleaning Equipment

Air & Water Driven Motors

Air and water-driven motors are the most common type of tube cleaners. They use high-pressure air or water to spin a brush or cleaning head inside the tube. This method effectively removes light to heavy deposits and is suitable for most applications.

Shoot-Thru Devices

Shoot-thru devices work by shooting a stream of high-pressure water or air through the tube to dislodge debris. Additionally, a variety of rubber plugs (pigs) and brushes can be shot through the tube to remove different types of scale. This method removes light to medium deposits and is often used in power plants and other industrial applications.

Rotary Style Cleaner

Rotary style cleaners use a rotating flex shaft to clean tubes. The shaft is inserted into the tube and rotated at high speeds, spinning a brush or descaling tool to remove debris. This method effectively removes light to medium deposits and is often by mechanical contracts in food processing, power generation, institutions, etc.

Cableless Tube Cleaner

Similar to the rotary style cleaner, the cableless cleaner uses water pressure instead of a spinning cable to provide the power for the brushing action. The cableless design eliminates downtime from replacing broken cables. This method effectively removes light to medium deposits and is suitable for chiller, condenser, and heat exchanger applications.

Why Clean Tubes?

To function efficiently, every tube-type heat exchanging device, whether a hot water or steam boiler, condenser, or an exchanger heating or cooling a liquid or gas, requires that the surface of the tubes be clean and scale-free.

The formation of mud deposits or hard or soft scale on the transfer surfaces of tubes can drastically reduce the flow of heat through the tube walls. These formations may consist of silicates, sulphates, sulphites, carbonates, calcium, organic growths etc. The fact is that all scale formations are insulators and therefore their presence in heat exchangers cannot be tolerated. Quite often, the fouling agents that cause scale also have chemical characteristics that are highly corrosive to the tube material.

In addition to the gradual but increasing loss of heat exchange efficiency, a build-up of scale on a tube's inner diameter gradually decreases the flow of either the coolant or the fluid to be cooled through the apparatus.

As the flow through the heat exchanger and the efficiency of the heater or cooler decreases, the entire system must work harder calling for increased pump capacity, increased flow of fuels, etc to overcome the deteriorating effectiveness of the device. This together with the possible damage to tube walls by the corrosive nature of some of the deposits creates a strong argument for maintaining scale-free heat transfer surfaces.

Tube Cleaning Made Simple: How to Locate a Reliable Tube Cleaning Equipment Manufacturer?

Realizing Why Clean Tubes Are Vital to Your Company

Understanding the significance of tube cleaning for your company is a prerequisite to learning about the criteria you should use to select a tube cleaning machine supplier. A well-maintained system can save money by decreasing breakdowns, raising output and quality, and minimizing defects. Costly equipment breakdowns, safety problems, and even regulatory infractions might result from ignoring tube cleaning. That's why it's so important to work with a reliable equipment provider for your company.

What to Look form

It is crucial to choose a tube cleaning machine supplier with extensive knowledge and a stellar reputation. A seasoned provider will have a thorough understanding of the several varieties of cleaning equipment, as well as their individual benefits and drawbacks. A reliable provider will have established themselves as a go-to for their clientele by consistently providing excellent service and goods.

Selection and Personalization of Products

The supplier's product selection and flexibility in terms of customization are also crucial aspects to think about. A reliable vendor will stock a variety of tube cleaning machines, both manual and automatic, to meet the needs of their customers. Machines should be adaptable to the diameter, length, and material specifications of individual tubes.

High-Quality and Long-Lasting

It is crucial to think about the quality and longevity of tube cleaning machines. If you're looking for a provider, make sure the machines they sell are built with high-quality materials and components. All machines should be put through a stringent quality control process to guarantee they are up to par with what customers want and what the industry requires.

Help with Technology and Maintenance

While looking for a supplier of tube cleaning machines, make sure they offer excellent technical support and service. Installation, training, and maintenance are just some of the technical support services that a reliable provider should offer. If they want their devices to perform at their best, they need to be able to respond quickly to customers' questions and offer reliable maintenance and repair services after the sale.

Cost and Economic Efficiency

Last but not least, think about how much money you'll save by going with a certain tube cleaning machine company. While cost is certainly a consideration, it shouldn't be the only one. Good value in terms of quality, durability, and technical support may be expected from a provider with reasonable pricing for their machines and services.

Assess Your Cleaning Needs

Before you dive into the world of tube cleaning equipment, take the time to assess your specific cleaning requirements. Are you dealing with a variety of surfaces that demand different cleaning methods? Consider whether you need to tackle challenging messes like chemical spills or sensitive areas that require specialist equipment.

Consider Facility Size and Layout

The size and layout of your industrial facility plays a significant role in determining the type of cleaning equipment you need. If you have vast open spaces, large floor scrubbers are likely to be the best choice. Alternatively, if your space has tight corners and narrow passages, compact machines would be more suitable. Don't forget to consider high-reach tools for cleaning ceilings and walls to ensure a thorough clean.

Prioritise Efficiency and Productivity

Efficiency is essential when it comes to industrial cleaning. Look for equipment that can perform the task effectively and productively. Consider the coverage area, speed of operation, water consumption, and drying time. Equipment that supports quick and effective cleaning while being easy to operate can significantly enhance productivity.

Emphasise Safety Features

Safety should always be a top priority in an industrial setting. Ensure that the cleaning equipment meets safety standards and incorporates features like anti-slip mechanisms and ergonomic designs to prevent accidents and injuries. Additionally, pay attention to noise levels, as excessively loud machines can disrupt the working environment.

Evaluate Maintenance and Durability

Cleaning equipment that's difficult to maintain can lead to downtime and increased costs. Opt for machines that are easy to clean, service, and maintain. It's also wise to enquire about the availability of replacement parts and the duration of the warranty. Choosing robust equipment can save you from frequent replacements and repairs.

Think Environmentally

A responsible approach to industrial cleaning includes considering the environmental impact of your equipment. Look for machines that are energy-efficient, use eco-friendly cleaning solutions, and minimise water and chemical waste. Consider scrubber dryers that recycle water for the ultimate in sustainable cleaning.

Ensure Training and Compatibility

The ability of your cleaning team to be able to operate and maintain the equipment is crucial. Choose equipment that's user-friendly and compatible with your existing cleaning processes. Cleaning machine manufacturers typically offer free of charge training with all equipment deliveries to ensure your cleaning teams are confident in using and maintaining the machines.

Set a Realistic Budget

While investing in quality cleaning equipment is essential, it's equally important to stay within your budget. Consider both upfront costs and ongoing expenses like energy consumption and maintenance. Compare different options to find the best balance between quality and affordability.

Precautions For Tube Cleaning Equipment

Safety measures

First make sure staff have received the necessary safety training and are wearing appropriate personal protective equipment such as goggles, gloves and earmuffs. The operation of tube cleaning equipment also requires special care to avoid injury to personnel from the high-pressure water sprayed.

Drainage and Waste Disposal

The cleaning process produces sewage and cleaning waste, which may contain hazardous materials. Ensure wastewater is properly handled and disposed of to comply with environmental regulations.

Preparation

Before starting cleaning, shut down and isolate the heat exchanger system to ensure no fluid is flowing through it. It is also necessary to prepare a cleaning machine and corresponding nozzles, hoses and other equipment.

High-pressure cleaning

Use a tube cleaning equipment to spray high-pressure water at an appropriate angle and spray intensity onto the internal and external surfaces of the heat exchanger. This helps strip away dirt inside and outside the tube. Keep a certain distance when cleaning to avoid damaging the pipes or increasing risks during the cleaning process.

Inspection and re-inspection

After cleaning is complete, inspect the heat exchanger to make sure dirt has been removed. Sometimes multiple washes are needed to completely remove stubborn dirt.

Preventative measures

To reduce future fouling accumulation, consider using appropriate preventive measures in the heat exchanger system, such as filters, water treatment systems, etc.

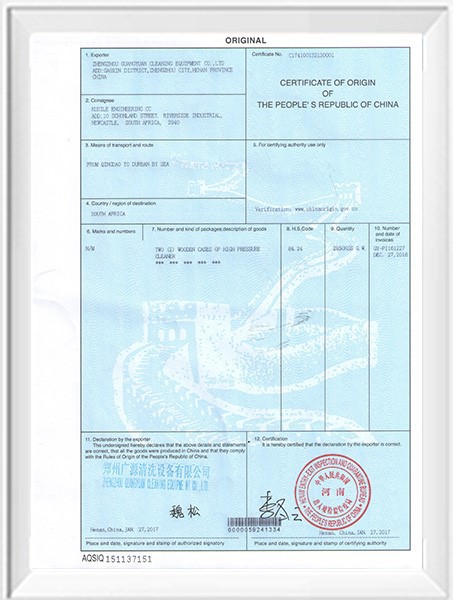

Our Certifications

Our company has obtained the following certificates:

Our Factory

We are professional in the design, manufacture and production of high pressure cleaning machine, water blaster, high pressure pump, cleaning system customization etc. Our cleaning machine can be applied in both industrial and commercial cleaning.

Ultimate FAQ Guide to Tube Cleaning Equipment

Hot Tags: tube cleaning equipment, China tube cleaning equipment suppliers, factory, hydro jet blasting machine, condenser cleaning equipment,

You Might Also Like

Send Inquiry