Hydro Water Sand Blasting Machine

Why Choose Us?

Variety of Products

We can design, customize and manufacture high-pressure cleaners, industrial cleaning machines, sewer drain cleaning machines, high-pressure pumps, pressure test pumps, automatic cleaning systems, etc. for customers. We can also provide a variety of related accessories.

Wide Range Of Applications

Our cleaning machines can be used in industrial and commercial cleaning applications. They can meet various needs such as commercial surface dirt cleaning, industrial pipe/pipe/tank cleaning, hull rust removal and painting, sewer drain cleaning, pipe/valve pressure testing, concrete surface roughening, concrete cutting, etc.

Advanced Production Equipment

Our factory is equipped with many advanced production equipment such as lathes, grinders, plate rolling machines, punching machines, and electric welding machines. We also conduct strict quality testing on our products to ensure they meet customer requirements.

Professional Service

We have a professional team to provide professional introduction and product recommendations. After the machine is manufactured, we will provide pictures and test videos for confirmation. In addition, we have a professional technical team to provide technical support to customers, and customers can enjoy our one-year warranty service.

What is Hydro Water Sand Blasting Machine?

Hydro water sand blasting machine has become more common day by day through ultra high pressure water often replacing the sand blasting. The uses of hydro blaster machine vary from paint and grease removal, tank cleaning and heat exchangers. Hydro blaster machine fairly simple to operate, they can be dangerous if not properly used. This pressurized water is pumped through ultra high pressure hose and discharged through a pipe called a lance which has the nozzle at the end.

Floor High Pressure Water Jet Cleaner

Designed for cold water use, it offers versatility in cleaning tasks where hot water is not required. Whether you need to clean machinery, vehicles, or outdoor surfaces, this high-pressure water jet cleaner provides the strength and efficiency needed for thorough cleaning. Its user-friendly design, durable construction, and reliable performance make it an ideal choice for industrial settings.

Floor High Pressure Water Jet Cleaning Machine

With its robust 22kW electric motor, this cleaner delivers high-pressure water jets to effectively remove dirt, grime, and contaminants from various surfaces. Designed for cold water use, it offers versatility in cleaning tasks where hot water is not required.

Floor High Pressure Cleaning Machine

Designed for cold water use, it offers versatility in cleaning tasks where hot water is not required. Whether you need to clean machinery, vehicles, or outdoor surfaces, this high-pressure cleaner provides the strength and efficiency needed for thorough cleaning. Its user-friendly design, durable construction, and reliable performance make it an ideal choice for industrial settings.

Floor Cleaning High Pressure Cleaner

22kW Electric Cold Water High Pressure Cleaner, a powerful cleaning solution for a wide range of applications. With its robust 22kW electric motor, this cleaner delivers high-pressure water jets to effectively remove dirt, grime, and contaminants from various surfaces.

High Pressure Water Sand Blasting Machine

Through wet sand blasting unit which uses high-pressure power washers to achieve rust and paint removal. The process of wet sand blasting produces to contaminating dust, making it safe for use in or around shipyard, marine, Anti-corrosion engineering, etc.

High Pressure Water Sand Blaster

The angle of attack and distance from the work surface may be varied to provide the best work speed, while still maintaining the greatest amount of impact energy. For optimum performance the sand inlet hose should not exceed 5 meters.

Industrial Tube Cleaning Water Hydro Blasting Machine

With its powerful diesel engine, this hydro jet cleaner provides the necessary force to generate high-pressure water jets, capable of dislodging and flushing away stubborn debris, grease, tree roots, and other obstructions that can impede the flow of wastewater. The diesel engine ensures consistent and reliable performance, making it suitable for heavy-duty cleaning tasks in both residential and commercial settings.

Industrial Tube Cleaning Water Hydro Blaster Cleaner

A robust and reliable solution for efficient and effective cleaning of sewer lines. Powered by a diesel engine, this hydro jet cleaner is designed to deliver high pressure water jets for clearing blockages and maintaining the integrity of sewer systems in various applications.

Industrial Tube Cleaning Hydro Blasting Machine

A robust and reliable solution for efficient and effective cleaning of sewer lines. Powered by a diesel engine, this hydro jet cleaner is designed to deliver high pressure water jets for clearing blockages and maintaining the integrity of sewer systems in various applications.

Advantages of Hydro Water Sand Blasting Machine

Safe

Sand blasting doesn't use any harmful chemicals or hazardous substances, which makes it completely safe for both surfaces and the environment.

Fast and Effective

Sand blasting doesn't take much time, so companies that choose this method won't need to pause their operations for very long in order to have their surfaces cleaned. Since it requires less time and is less labour-intensive, hydroblasting also tends to be more cost-effective than other surface cleaning techniques.

No Surface Damage

Sand blasting generally never damages the surface it's washing, which isn't always the case with other types of cleaning techniques. Although the water pressure used is considerable, it's harmless for materials that can withstand exposure to water and moisture.

Effective on Hard-to-Reach Areas

Sand blasting can clean areas that are difficult to reach. The nozzle can be used to aim the jet of water very precisely, dislodging dust and grease that might otherwise have gone unnoticed.

No Particles or Residue

Sand blasting doesn't generate any particles. There won't be any abrasive residue left over after cleaning. The only remnants to take care of will be the water and dislodged debris.

Sandblasting is now commercially used by big industries. If you are looking for sandblasting machine then sand blasting is for you with Quality Abrasive Sandblasting Cabinets. If you are an online shopper then the will give a chance to find a custom building bead blast cabinet, or any other type of abrasive blast cabinet, Sand blasting is the process to roughen or clean a surface with a jet of sand driven by compressed air or steam. Quality Abrasive Sandblasting Cabinets does this task for you specially in industrial and construction industry. Further a sandblasting cabinet is an abrasive blasting method used to remove deposits of surfaces without damaging the original surfaces. Generally, a blast cabinet is used to remove calcium buildup from fungus deposits or pool tiles and it can also be used as a means to brighten grout which has faded, due to a build up of dirt or contaminants. Sand blasting is also known as abrasive blasting. It is a process where fine granular sand is applied high pressure against a rough surface keeping in mind the end goal to smooth that surface out. In this process, the abrasive material is pushed, either with a fluid or a gas (ordinarily pressurized air) through a nozzle onto an odd surface. Sand blasting can be applied on wood, dividers, and different surfaces where smoothness is required for paint or different applications. Sandblasting Services Providers in China.Sand blasting is a quick, powerful, thorough, and safe process it is one of the best ways to prepare an object for high-performance coatings like powder coating.

Hydro water sand blasting machines support parts made of different types of materials. The list of parts based on their material type is given below:

Aluminum Parts

The majority of parts that undergo the blasting process are made up of aluminum.

Carbon Fibre Parts

Carbon fiber parts are used in many sectors like medical, aerospace, mechanical, automotive space, etc.

Stainless Steel Parts

You can also use stainless steel parts for blasting.

Rubber Parts

Rubber parts are widely used in almost all sectors and industries.

Chrome Parts

Chrome parts are used in the automotive, mechanical, and aerospace segments.

Steel Parts

When your parts are made of steel, you must use an anti-rust solution and water for blasting.

Brass Parts

Brass parts can also be used inside a blasting machine.

Application of Hydro Water Sand Blasting Machine

Sensitive Surfaces

Some surfaces are very sensitive, vulnerable, soft, or fragile. Waterblasting is the ideal way to prepare and treat these types of surfaces. This is because water is a softer material than the abrasive material used in sandblasting. The pressure can also be amended as needed to ensure that the process does not damage the surface that you are working on. Sensitive surfaces that may be waterblasted include those involved in antique restoration; wood restoration, removing graffiti, or cleaning automotive parts.

Projects with Soft Metal

Waterblasting does not cause heat. This is especially important for softer metals, which may warp if subjected to higher temperatures. Waterblasting helps to keep the soft metal cool, preventing distortion and damage. This is why it is often the best method for treating metals such as stainless steel and aluminum.

Working in Urban Environments

There are many safety regulations in urban environments that are in place to protect public health. This includes airborne dust. This means sandblasting is not allowed or is not the best option if you are working in an urbanized area. Instead, waterblasting is the safest method of surface preparation in these areas. The water suppresses most of the dust, meaning that this is not a concern or issue. Work can continue in a safe and law-abiding way.

Vehicle Parts

Waterblasting is often used to prepare and treat vehicle parts. This includes both automotive and motorcycle. Waterblasting can be used to remove common dirt, grease, rust, coatings, and other materials that are on the parts. The process can help to improve vehicle performance or restoration projects. Using waterblasting means that this cleaning and stripping process is quick, and produces a soft finish. After waterblasting the surfaces the finished results have a satin-like finish.

Industrial Environments

Waterblasting is the safest method of surface preparation in industrial environments. If you decide to sandblast a surface, the abrasive hits the surface with high power and impact. This abrasive splits into smaller particles which causes dust. This dust has the potential to create dry sparks. If flammable materials are nearby, there is a real risk of a fire or explosion. That is why businesses use waterblasting in these industrial environments. This method has a very small possibility of creating sparks.

Engineering and Aerospace Environments

Waterblasting is often used in engineering and aerospace environments. This is an effective and efficient way to remove any contaminants on equipment or materials. This can be incredibly helpful to ensure that machinery and tools are working correctly and safely, without causing any unnecessary or unplanned damage to sensitive equipment.

The History of Hydro Water Sand Blasting Machine

Vapor blasting was first used and developed in England during World War II by Rolls-Royce. He used this method to peen and finish the surfaces of turbine blades. Waterblasting became a tool used for jet engine builds.

By 1950, crystalline silica was banned in England. It was being used in sandblasting, but workers were developing silicosis; a terminal respiratory disease. Later in the same decade, Norman Ashworth developed the first waterblasting equipment as an alternative method for surface preparation, which didn't involve any crystalline silica.

By 1966, many European countries had done the same. Sandblasting procedure with crystalline silica was banned because of the health risks it posed to those working with it. People moved towards waterblasting as a safe and efficient alternative.

The development of waterblasting led to outdoor waterblasting units developed in Europe from the 1970s onwards. It has become increasingly popular, used across the globe for safe and efficient surface preparation.

How Hydro Water Sand Blasting Machines Works?

Start the high pressure system and adjust the water flow and system pressure with your nozzle selection, pump rpm and regulating unloader setting. Open the trigger on gun to assure system is operating properly. Place the sand induction probe in the sand supply container. With the trigger on the gun open, adjust the small valve on the mixing head. The adjustment creates a vacuum in the sand hose line and starts the flow of sand. The sand is drawn into the system through the sand point directly from a container. The head features suction capabilities to then draw the sand through the sand pickup tube into the head. The sand is then mixed with high-pressurized water in the head. The resulting mixture of sand and water is forced through the nozzle across surfaces at high pressure levels. The pressure washer sandblaster should be approximately 12 to 15 inches away from the work surface when the trigger is opened and the water sand blaster operation begins.

Hydro Water Sand Blasting Machine and the Construction Industry

Industrial strength cleaning applications are vital within the construction industry, especially in the eradication of dirt and other undesirable materials from structures and surfaces.

In fact, ultra-High Pressure Water jetting is the preferred method of choice on projects where large amounts of abrasives must be collected and disposed of. Several studies have even shown that surfaces that have been water blasted with high pressure water blasters, are cleaner than those blasted using traditional solid abrasive methods.

High pressure water blasting not only removes old coatings and rust, it also eliminates deeply embedded crystallized salt, resulting in a remarkable reduction of chloride levels on surfaces leading to higher adhesion of coating and longer coating life.

Utilizing high pressure washing technology also allows construction work to be undertaken in areas where other conventional blasting methods would be impossible to use, e.g. terminals, refineries and urban areas, making the use of this cleaning method crucial in the construction industry due to its ability to adapt to the requirements of almost any space.

Personnel hydro water sand blasting machine that are exposed to will wear a raincoat, rubber pants, safety glasses, hardhat with face shield, rubber boots and gloves. Hearing protection will also be worn. These do NOT provide protection from the jet but do protect against hazards encountered while performing the work.The following identifies at a minimum the personal protective equipment that will be issued to employees performing high-pressure water cleaning outside of the required hardhat and safety glasses with side shields:

Face shields – Clear shield nine inches deep by fifteen and one-half inches wide by 0.60 thick (ANSI Z87.1-1979 or equivalent).

Rain Suit – Made of nylon fabric coated with Neoprene on both sides.

Gloves – Made of Neoprene, rubber and PVC with rough wet grip finish.

Rubber steel-toed boots – Knee length with ribbed steel shanks and heavy tread soles for nonslip traction (ANSI Z41.1-1967 or equivalent).

Metatarsal Guards – Designed to be worn with lace-type steel toe boots.

When cleaning equipment which could possible be contaminated with hazardous chemicals, appropriate additional protection specified by the project management/safety will be worn by the operator as well as other employees who may be affected.

The time duration for running the machine depends on many factors.

Finish requirement

You will have to run the machine for a longer duration if you want to achieve a high gloss finish.

The finishing time will be less for a matte finish.

Material type

The finishing time will be less for soft metals like aluminum and brass.

The time taken will be more for hard metal and metal alloys.

Surface Preparation

If you are looking for surface preparation of parts before coating or painting, then the finishing time will be less.

Blast media

The time duration of the process is also dependent on the blast media.

A media with a higher cutting rate can bring down the processing time drastically.

But, you should ensure that such cutting rates does not damage your parts.

A high quality media can also help to bring down the processing time.

So, never invest in cheap low quality blast media.

Despite its many benefits, ultra high pressure water jetting maybe not the perfect for every job, find out which option best suits your cleaning, please talk to our experienced sales or engineer.

Hydro blasting works like a a power washer that is contained in a housing the size of a large lawnmower. It blasts the surface with a high pressure water stream. The water is immediately sucked back into the pump system so the surface is not only clean . and free of the original asbestos, also get dry easy . Surface preparation is essential prior to make the new painting, coating or lining of a substrate. To ensure that the material is applied consistently. free from contamination or debris affecting the quality of the final surface. Grit jetting and UHP water jetting are common choices for producing a clean surface and both methods produce comparable high quality results. so knowing which is more better for your project can be tricky.

Pump Anti Vibration Technology of Hydro Water Sand Blasting Machine

●The pump anti vibration technology reduces vibration during pumping by 50% allowing less movement and greater control of the end hose.

●The one button stabilization technology quickly dampends any pump movement resulting from repositioning the piston. This allows precise positioning of the end hose.

●With cycle times of up to 29 per minute (at 12MPa), pump efficiency is increased up to 25% while fuel consumption is decreased by up to 10%.

●The hydraulic system developed by an international team ensures precise operation and energy conservation.

●Extra reinforcements in the boom, arm, swing platform and undercarriage increase stability and service life. Easily accessible service points and a detachable radiator screen are among the features that make scheduled maintenance more convenient.

How to Operate Hydro Water Sand Blasting Machine?

Turn on the power and open the cabinet. Then add water and feed the machine according to its model.

When you turn on the power supply, the abrasive pump runs automatically. Put the workpiece into the box and close the work compartment door.

Hold the spray gun in the right hand and stabilize the workpiece to be processed with the left hand. Step on the footswitch after which the wiper will start automatically causing the abrasive and water to pass.

The air source then flows into the spray gun at high speed and directly hits the parts to be processed to achieve the effect of sandblasting. The thickness of the processed workpiece can be selected by the abrasive.

After sandblasting is completed, release the footswitch to stop the spray gun. Open the work compartment and take out the parts.

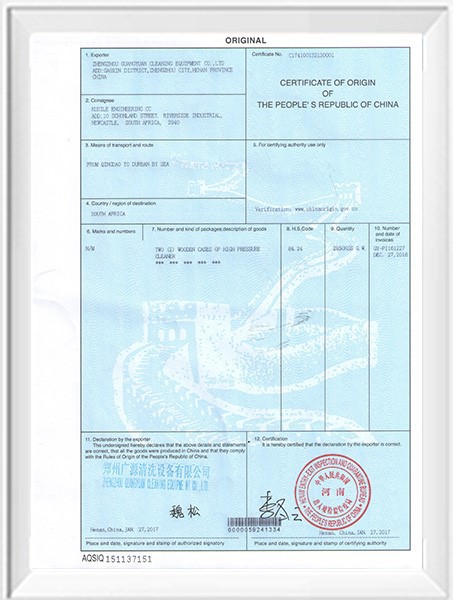

Our Certifications

Our company has obtained the following certificates:

Our Factory

We are professional in the design, manufacture and production of high pressure cleaning machine, water blaster, high pressure pump, cleaning system customization etc. Our cleaning machine can be applied in both industrial and commercial cleaning.

Ultimate FAQ Guide to Hydro Water Sand Blasting Machine

| Model | GYB-500 |

| Speed | 1480 rpm |

| High pressure pump | Triple plunger pump |

| Pump head material: copper | |

| Plunger material:ceramic | |

| Rate Pressure | 500 bar / 7250 psi |

| Water flow | 23 L/min |

| Plunger dia. | 18mm |

| Diesel engine | 33kw, 4-cylinder HD brand; |

| Electric power | 22kw, 3Phase, 380v/50Hz or 440v/60Hz |

Hot Tags: hydro water sand blasting machine, China hydro water sand blasting machine suppliers, factory, , pipe cleaning equipment, heat exchanger cleaning system

Previous

1000bar Water Jet CleanerYou Might Also Like

Send Inquiry