Pressure Testing Pump

Why Choose Us?

Variety of Products

We can design, customize and manufacture high-pressure cleaners, industrial cleaning machines, sewer drain cleaning machines, high-pressure pumps, pressure test pumps, automatic cleaning systems, etc. for customers. We can also provide a variety of related accessories.

Wide Range Of Applications

Our cleaning machines can be used in industrial and commercial cleaning applications. They can meet various needs such as commercial surface dirt cleaning, industrial pipe/pipe/tank cleaning, hull rust removal and painting, sewer drain cleaning, pipe/valve pressure testing, concrete surface roughening, concrete cutting, etc.

Advanced Production Equipment

Our factory is equipped with many advanced production equipment such as lathes, grinders, plate rolling machines, punching machines, and electric welding machines. We also conduct strict quality testing on our products to ensure they meet customer requirements.

Professional Service

We have a professional team to provide professional introduction and product recommendations. After the machine is manufactured, we will provide pictures and test videos for confirmation. In addition, we have a professional technical team to provide technical support to customers, and customers can enjoy our one-year warranty service.

What is Pressure Testing Pump?

A pressure testing pump is a device that is used to apply pressure to a pressure vessel or pipe system. It is typically a positive displacement pump, which means that it displaces a fixed volume of fluid with each stroke. This allows the pump to build up pressure in the system gradually.

A high-pressure water jet pump is a formidable machine designed to generate an intense, concentrated stream of water at incredibly high pressures. This powerful jet, often pressurized to thousands of pounds per square inch (psi), becomes a dynamic force that can be harnessed for a wide range of applications.

Hydro testing equipment is commonly used in industries such as oil and gas, manufacturing, plumbing, and construction to ensure that pipelines, vessels, valves, and other pressure-containing elements can withstand the specified operating.

The high-pressure pump used in this equipment introduces advanced technology from German WOMA; horizontal stainless steel pump head; stainless steel nickel-plated alloy plunger, forced water cooling. The high-pressure pump box body is made of ductile iron; it has good heat dissipation, hard texture and is not easy to deform.

High Pressure Hydro Jetting Pump

Industrial tube Pipe Cleaning: In industrial settings, pipes and tubes can become fouled with scale, sludge, or other contaminants. Hydro jetting pump is an efficient method to clean these pipes without the need for harsh chemicals or disassembly.,Hydro jetting pumps are employed to remove these deposits, restoring the optimal flow and heat transfer capabilities of the systems.

The hydro testing machine produced by our company has the characteristics of compact and reasonable structure, labor-saving operation, light weight of the whole machine, easy maintenance, and anti-rust. The DSY electric pressure test pump is driven by a motor, which greatly improves work efficiency.

Introducing Industrial Pipe Cleaning Pumps An industrial pipe cleaning pump is a specialized powerhouse, meticulously designed to address the unique challenges of pipeline maintenance. From large-scale manufacturing plants to expansive petrochemical facilities, these pumps are indispensable assets, capable of restoring pipelines to their optimal condition.

High Pressure Triplex Plunger Pump

Triplex plunger pump is Three plunger reciprocating water jet high pressure pump, Main parts for high pressure cleaning equipment.

Pressure testing pump is use high pressure water jetting way to testing the pipe and valve withstand pressure and burst pressure

Features of Pressure Testing Pump

Pressure Generation

Pressure testing pumps are designed to generate high-pressure fluids, which are then used to subject the test material to the desired pressure levels. The pumps can often be calibrated to deliver precise pressures.

Pressure Control

These pumps offer the ability to control and maintain a consistent pressure level during testing, ensuring accurate and repeatable results.

Safety Measures

Safety valves, pressure relief mechanisms, and pressure gauges are integrated into hydrostatic test pumps to prevent overpressurization, safeguarding both the pump operator and the test material.

Portability

Many pressure testing pumps are designed to be portable, allowing them to be transported to various testing sites, including remote locations or construction sites.

Versatility

Pressure testing pumps are versatile tools that can be used for a wide range of materials and applications, from small cylinders to large pipelines.

Types of Pressure Testing Pump

Hydrostatic Testing Pump

Hydrostatic testing Pump utilizes water or another liquid as the testing medium. It is commonly used for testing piping systems, pressure vessels, and other components that are designed to handle liquids. The working principle involves applying hydraulic pressure to the test object, gradually increasing the pressure until it reaches the desired test pressure or until a failure occurs.

Air Pressure Testing Pump

Air pressure testing Pumps utilize compressed air as the testing medium. They are commonly used for testing components that are designed to handle compressed air, such as pneumatic systems, valves, and actuators. The working principle involves applying pneumatic pressure to the test object, gradually increasing the pressure until it reaches the desired test pressure or until a failure occurs.

Burst Pressure Testing Pump

Burst pressure testing Pumps are designed to determine the maximum pressure a component can withstand before failing. They are commonly used for testing components that are subjected to extreme pressure conditions, such as hydraulic hoses, pressure vessels, and safety valves. The working principle involves applying increasing pressure to the test object until it bursts or reaches a predetermined pressure limit.

Application of Pressure Testing Pump

Hydrostatic Test for Boilers

Hydro testing a boiler is one approach to ensure that the tubes, flanges, fittings, and connections are properly sealed. On new boilers or after any major pressure vessel work, this test is performed. A hydro pump is used to help fill the boiler with water to start the test. The water is poured into the vessel to 1.5 times the maximum permitted working pressure (MAWP).

Pipe manufacturers

Pipes of various lengths will be hydrostatically tested at commercial pipe manufacturing factories, particularly those supplied to government organisations. They must demonstrate that each pipe fits specifications and will not fail in important applications such as naval defence vessels.

Cooling systems

A/C or refrigeration cylinders or coils are routinely checked, especially in buildings where climate control is vital, such as hospitals. Such types of refrigerants are even used in cooling electronics in industrial electrical enclosures, as well as military vehicles operating in hot climates. Cooling systems are also used in municipal vehicles such as city buses, and some state Departments of Transportation may demand frequent testing to guarantee safety and good operation.

Fire hoses

Critical applications such as fire hoses must be thoroughly tested to guarantee that they do not rupture or fail while in use. They're usually put through their paces before being mounted on fire trucks or sent to fire stations. Inspectors will fill hoses with fluid and pressurise them to a minimum of 300 PSI, as specified by the National Fire Protection Association (NFPA).

Sprinkler systems

Many sprinkler systems are required by code to be tested on a regular basis to guarantee that they can sustain pressure and work properly when activated. A pump is connected to the main sprinkler system line and inflated to 250 PSI for at least 15 minutes.

The Main Components Of Pressure Testing Pump

Most hydrostatic test pumps rely on piston- or plunger-type pumps that work best with pressurized water supplies. In order to use them with a non-pressurized water source, starting a gravity feed-essentially, using gravity as the pressure source needed to flow water into the pump-is typically enough to create positive flow. Simply place the pump at a lower elevation than the container holding the supply of water, turn it on with the priming valve open, and let gravity do its work.

Hydrostatic test pump motors generally rely on three main power sources: battery power, plug-in electric, and gas. Motor size, or horsepower, is determined by the amount of pressure and volume required. Here's a word to the wise: For plug-in electric and battery-powered pumps, don't forget to check whether the power source meets the motor's electrical requirements. That includes any voltage, phase, hertz, and amperage requirements noted by the manufacturer. It's also important to check whether the pump's parts have enough oil and any other needed fluids before testing begins, including the engine crankcase, gear reduction, and gas tanks.

Fire protection systems-especially small ones-can pressurize very quickly. To avoid damage, some pumps, include pressure regulators that keep pressure in check without minute-by-minute monitoring. Regulators can be preset to close off the water supply after detecting that the outlet pressure has hit a specific number. A full-flow bypass then diverts water directed at the outlet hose back into the pump itself.

Hydrostatic test pumps include a gauge that indicates the pressure supplied to the system. Read this carefully: that's different from system pressure, which is measured by a separate gauge. A test pump's gauge must be capable of reading up to two times the maximum pump pressure. Put simply, if the pump is rated for 300 psi, the gauge must be able to read at least 600 psi. Generally, the middle of the scale on the gauge offers the most accurate readings.

Test pumps come equipped with electrical cords and hoses that provide the flexibility needed to connect to a fire protection system during testing. Long lengths of cable stretch over long distances, making it easier to connect to a battery in a parked vehicle. Other electric pumps come with shorter lengths of cord-most often, six feet-that can be combined with standard extension cords if needed.

How Does Pressure Testing Pump Work in a Home's Sewer System

Trees are always searching for reliable sources of water. They send their roots in every direction to find moisture. Sewer pipes are an attractive source. The tree sends microscopic root tendrils into the tiniest opening. If it finds a place to get inside, the root will start drawing moisture from that source. This triggers the root to grow bigger, which forces the opening to become larger. In time, the roots can crack the pipe and cause it to break.

Pressure testing helps plumbers find these hidden leaks. It starts by finding the drain line's cleanout. The plumber inserts an inflatable test ball into the cleanout. The ball gets inflated to block the sewer line, usually close to the foundation's edge.

With the main sewer line blocked, the plumber fills it with water, up to the slab's top edge. Then, it's a matter of waiting. The plumber waits to see if the water level starts to drop. If it does, there's a leak under the building's slab.

The next step is to find out where the leak is. One option is to feed a video camera down into the sub-slab pipes to find the location of the leak. It also offers the ability to inspect the general condition of those pipes.

Another option is to use inflatable plugs to isolate and test different sections of pipe. The plumber uses the video camera to position the plugs to different points. This makes it possible to isolate and test different sections of the pipe.

How to Use a Pressure Testing Pump?

To use a pressure testing pump, you will need to follow these steps:

Connecting the pump to the pressure vessel or pipe system

The pump must be connected to the pressure vessel or pipe system in a way that ensures that the pressure is evenly distributed throughout the system. This is typically done by using a pressure gauge to monitor the pressure and adjusting the pump as needed.

Filling the pressure vessel or pipe system with water

The pressure vessel or pipe system must be filled with water before the pressure can be increased. This is done to ensure that there are no air pockets in the system, which could cause the pressure to be uneven.

Pressurizing the system to the desired PSI

The pressure is gradually increased until it reaches the desired level. The desired level of pressure is typically specified by the manufacturer of the pressure vessel or pipe system.

Maintaining the pressure for the specified amount of time

The pressure is then maintained for a specified amount of time. This allows any leaks or weak spots in the system to be detected. The amount of time that the pressure is maintained is typically specified by the manufacturer of the pressure vessel or pipe system.

Releasing the pressure and disconnecting the pump

Once the specified amount of time has elapsed, the pressure is released and the pump is disconnected from the pressure vessel or pipe system.

To grasp the intricacies of a pressure testing pump, one must delve into its fundamental working principle, which hinges on the remarkable discovery known as Pascal's law. This law, named after the French mathematician and physicist Blaise Pascal, states that when pressure is applied to a confined fluid, it transmits that pressure undiminished in all directions. This phenomenon forms the bedrock of hydraulic systems and plays a pivotal role in the operation of Pressure Testing Pumps.

When a hydrostatic test is performed, the test pump utilizes this principle to subject various materials or systems to elevated pressures. The process involves filling the object or pipeline with an incompressible fluid, often water, and then gradually increasing the pressure using the test pump. As the pressure mounts, it gets uniformly distributed throughout the fluid and consequently applies equal force to all surfaces within the confined space. This mimics the stress conditions that the material or system would encounter during its regular operation.

The real magic of the pressure testing pump lies in its ability to expose potential vulnerabilities that might otherwise remain concealed. As the pressure builds, any weak points, defects, or imperfections in the material's structure become apparent. These could manifest as leaks, cracks, or deformations that indicate the material's inability to withstand the designated pressures. By detecting these flaws early on, the Pressure Testing Pump ensures that the tested object is safe, reliable, and fit for its intended purpose.

In essence, the working principle of the pressure testing pump is a testament to the interconnectedness of fluid dynamics and mechanics. It capitalizes on the remarkable property of fluids to transmit pressure uniformly, unveiling the hidden characteristics of materials and systems under rigorous stress conditions. Through this principle, pressure testing pumps act as sentinels of safety, providing a safeguard against potential hazards and ensuring that the engineered world stands strong against the forces it encounters.

6 Points To Consider While Selecting A Pressure Testing Pump

Initial Pressure

Generally, a filling pump is required to provide the water in the pump, for which some pressure is always there. It is a vital point to discuss with the manufacturer.

Pressure

It is the most basic selection criteria. You must choose the hydraulic pressure testing pump that has more pressure than you require at the moment, as you may need more pressure in the future. It is advisable to take the pump with 10-20 % more pressure.

The Number Of Tests

You can inform the frequency of the tests you need to take, as the manufacturer can suggest to you the right pressure pump for your requirements.

The Volume Of The Equipment

You can either inform the flow rate or the volume of the equipment to the pressure testing pump We advise you to inform volume, as you may assume flow rate proportional to the volume of the equipment; which may be found wrong when it comes to large equipment. On the basis of the volume, the manufacturer can suggest you right pressure pump.

Efficiency

You need to ensure that you buy the pump with utmost efficiency. These three parameters can help you measure it. Volumetric, mechanical, and overall performance.

Time

It is also essential to know how much time you have for developing pressure through the pump. If you have enough time, a smaller pump can be purchased.

A wide range of materials can be subjected to pressure testing. These materials include but are not limited to:

Pipelines

Pressure testing pumps are frequently employed to test the integrity of pipelines, whether they are used for transporting water, oil, gas, or other fluids. Ensuring that pipelines can withstand the pressures they are subjected to is paramount to prevent leaks or ruptures.

Pressure Vessels

Pressure vessels, used in various industries to store gases or liquids at high pressures, must undergo rigorous testing to avoid catastrophic failures. Hydrostatic testing helps identify potential flaws in welds, seams, or materials, ensuring that the pressure vessel is fit for operation.

Boilers

In industries such as power generation, hydrostatic testing of boilers is essential to detect any weaknesses that could lead to steam or water leaks, which can have dire consequences in terms of safety and operational efficiency.

Fire Extinguishers

Fire extinguishers are tested using hydrostatic pressure to verify their structural integrity and ability to contain the extinguishing agent under pressure.

Cylinders

Cylinders used in various applications, such as gas storage or hydraulic systems, are also subject to hydrostatic testing to ensure they can withstand the pressures they encounter during their operation.

Safety Precautions When Using Pressure Testing Pumps

Personal Protective Equipment (PPE)

Operators should always wear appropriate PPE, including safety goggles, hearing protection, gloves, and appropriate clothing. These items are essential for protecting against potential hazards such as high-pressure water spray and noise.

Handling High-Pressure Equipment

High-pressure water can be extremely dangerous if it comes into contact with the body. Avoid standing directly in front of hoses or fittings when pressurized and keep body parts away from high-pressure streams. Secure hoses and fittings to prevent sudden bursts or disconnections.

Pressure Control

Carefully monitor pressure gauges throughout the testing process. Avoid over-pressurization, which can lead to equipment failure and potential hazards. Follow the recommended pressure limits for the specific test being conducted.

Avoiding Pinch Points

Be cautious around moving parts of the test pump, especially if it has mechanical components. Ensure that hoses are properly routed and secured to prevent pinching, which can lead to damage or rupture.

Proper Ventilation

If testing indoors or in confined spaces, ensure adequate ventilation to disperse any fumes or vapors that may be present. Avoid working in areas with poor air circulation, as this can lead to health and safety risks.

Emergency Procedures

Operators should be trained in emergency procedures, including how to quickly shut down the pump and release pressure in case of an emergency. First aid kits and medical assistance protocols should be readily available in case of injuries.

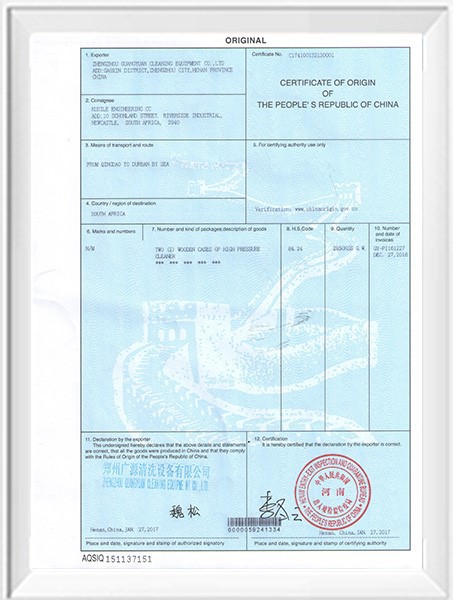

Our Certifications

Our company has obtained the following certificates:

Our Factory

We are professional in the design, manufacture and production of high pressure cleaning machine, water blaster, high pressure pump, cleaning system customization etc. Our cleaning machine can be applied in both industrial and commercial cleaning.

Ultimate FAQ Guide to Pressure Testing Pump

Hot Tags: pressure testing pump, China pressure testing pump suppliers, factory, pipe cleaning equipment, , , heat exchanger cleaning system, High Pressure Hydro Jetting Pump

Previous

No InformationYou Might Also Like

Send Inquiry